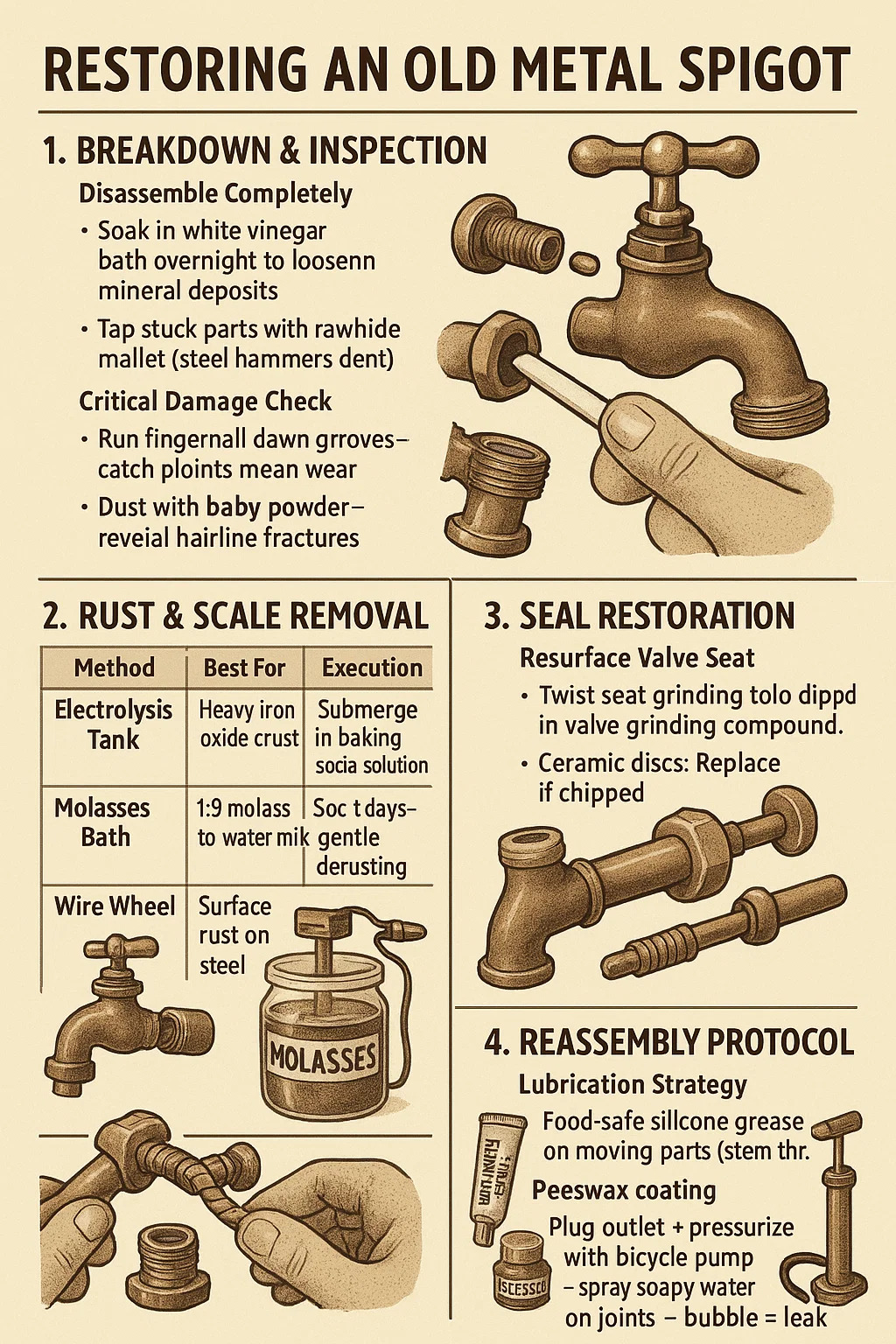

Restoring an Old Metal Spigot

一、Breakdown & Inspection

Disassemble Completely

Soak in white vinegar bath overnight to loosen mineral deposits.

Tap stuck parts with rawhide mallet (steel hammers dent brass).

Critical Damage Check

Threads: Run fingernail down grooves—catch points mean wear.

Seat surfaces: Shine flashlight into valve chamber—pitting leaks pressure.

Cracks: Dust with baby powder → reveals hairline fractures as dark lines.

二、Rust & Scale Removal

| Method | Best For | Execution |

| Electrolysis Tank | Heavy iron oxide crust | Submerge in baking soda solution + battery charger (sacrificial steel anode) |

| Molasses Bath | Bronze/brass preservation | 1:9 molasses-to-water mix, soak 7 days—gentle derusting |

| Wire Wheel | Surface rust on steel | Brass bristles only (steel wheels scar metal) |

三、Seal Restoration

Resurface Valve Seat

Brass seats: Twist seat grinding tool dipped in valve grinding compound.

Ceramic discs: Replace if chipped—polishing destroys glaze.

Reform Packing Gland

Remove old packing material → wrap graphite-impregnated rope around stem → compress with gland nut.

四、Reassembly Protocol

Lubrication Strategy

Food-safe silicone grease on moving parts (stem threads).

Beeswax coating on exterior—repels water without attracting dirt.

Pressure Testing

Plug outlet → pressurize with bicycle pump → spray soapy water on joints → bubble = leak.

English

English русский

русский 日本語

日本語 عربى

عربى Español

Español