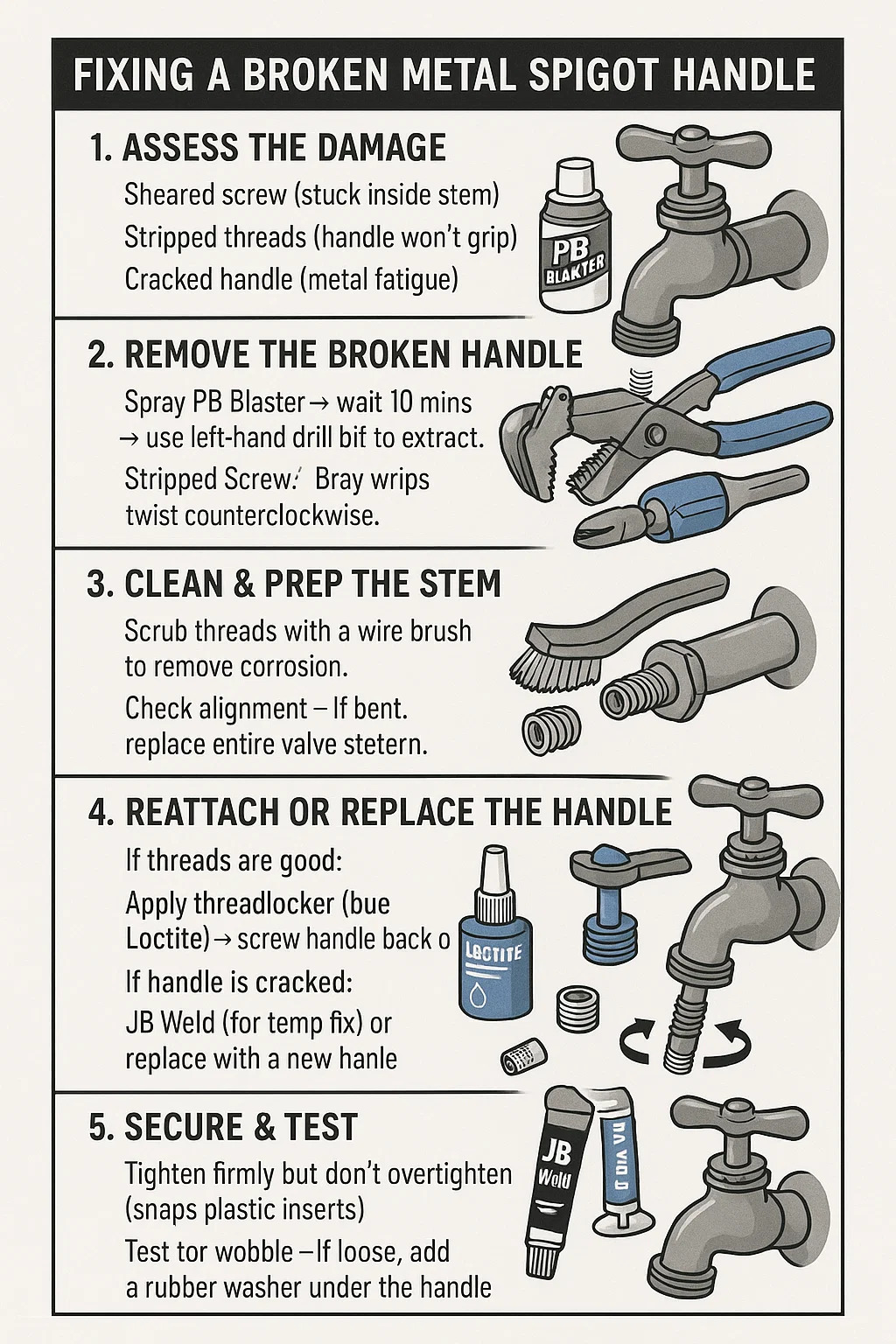

Fixing a Broken Metal Spigot Handle

1. Assess the Damage

Type of Break:

Sheared screw (stuck inside stem)

Stripped threads (handle won’t grip)

Cracked handle (metal fatigue)

2. Remove the Broken Handle

Stuck Screw? Spray PB Blaster → wait 10 mins → use left-hand drill bit to extract.

Stripped Screw? Grip with vise-grips and twist counterclockwise.

3. Clean & Prep the Stem

Scrub threads with a wire brush to remove corrosion.

Check alignment – If bent, replace the entire valve stem.

4. Reattach or Replace the Handle

If threads are good:

Apply threadlocker (blue Loctite) → screw handle back on.

If threads are stripped:

Tap new threads (use a M6 x 1.0 tap for most spigots).

Use a repair sleeve (thread insert like Heli-Coil).

If handle is cracked:

JB Weld (for temp fix) or replace with a new handle.

5. Secure & Test

Tighten firmly but don’t overtighten (snaps plastic inserts).

Test for wobble – If loose, add a rubber washer under the handle.

| Step | Action | Tool/Material | Pro Tip |

| Damage Assessment | Identify break type (sheared screw/stripped threads/cracked handle) | Flashlight, magnifier | Shine light at 45° angle to reveal hairline cracks |

| Removal | For stuck screws: Penetrating oil + left-hand drill bit extraction | PB Blaster, extractor set | Heat with lighter first if plastic components present |

| Thread Repair | Clean with brass brush, re-tap if stripped | Thread chaser set, wire brush | Always cut new threads clockwise to match original |

| Handle Reattachment | Use threadlocker for intact threads | Blue Loctite #243 | Let cure 1 hour before use - sets faster with metal |

| Replacement Options | For cracked handles: epoxy temp fix or full replacement | JB Weld, replacement handle kit | Keep original handle brand for perfect fit |

English

English русский

русский 日本語

日本語 عربى

عربى Español

Español