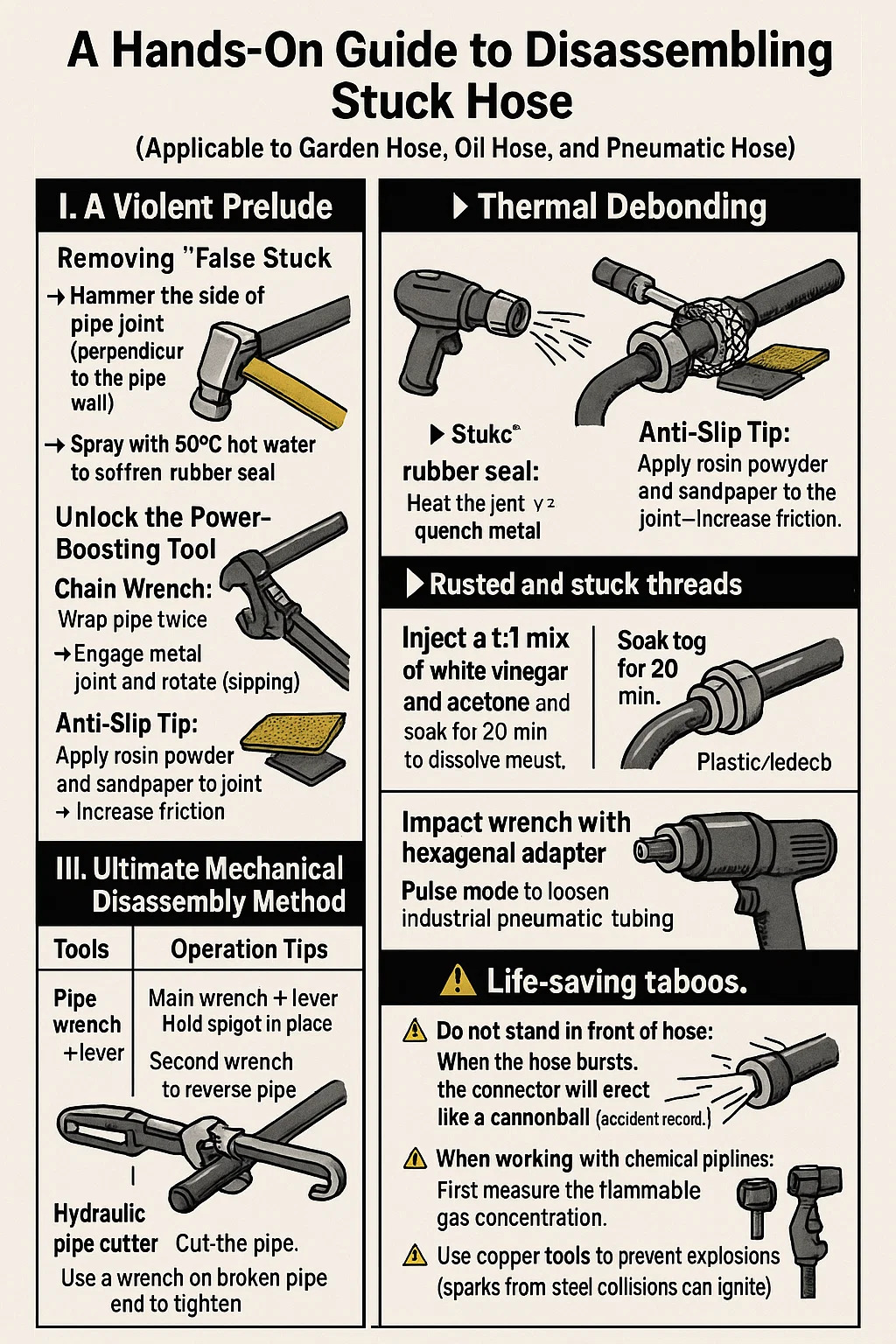

A Hands-On Guide to Disassembling Stuck Hose

(Applicable to Garden Hose, Oil Hose, and Pneumatic Hose)

I. A Violent Prelude

Removing "False Stuck"

Hammer the side of the pipe joint (perpendicular to the pipe wall) → Shake out scale crystals

Spray with 50°C hot water to soften the rubber seal (avoid boiling water; it accelerates aging).

Unlock the Power-Boosting Tool

Chain Wrench: Wrap the pipe twice → Engage the metal joint and rotate (to prevent slipping).

Anti-Slip Tip: Apply rosin powder and sandpaper to the joint → Increase friction.

II. Thermal Debonding

▶ Stuck Rubber Seal: Heat the joint with a heat gun on low setting for 15 seconds → Use an ice pack to quench the metal → Shrink and separate the rubber.

No Blowtorches! High temperatures damage the pipe's memory layer.

▶ Rusted and stuck threads.

Inject a 1:1 mixture of white vinegar and acetone and soak for 20 minutes to dissolve the rust.

III. Ultimate Mechanical Disassembly Method

| Tool | Operational Secret | Ideal Scenario | Tool Stance |

|---|---|---|---|

| Pipe Wrench + Cheater Bar | Lock primary wrench on spigot → Counter-grip hose with second wrench → Cross-handle torque | Metal hose fittings | Feet braced wide – prevents face-plant when it breaks loose |

| Hydraulic Pipe Cutter | Sever hose → Jam cut end onto wrench drive → Leverage stump for rotation | Plastic/rubber hoses | Cut 2" from fitting – maximizes grip surface |

| Impact Wrench | Attach hex adapter socket → Pulse mode shocks (not rotates) | Industrial pneumatic lines | Low-angle hold – lets tool kick safely downward |

IV. Life-saving taboos.

*Do not stand in front of the hose: When the hose bursts, the connector will eject like a cannonball (accident record: penetrated 3cm of wood).

*When working with chemical pipelines: First measure the flammable gas concentration.

*Use copper tools to prevent explosions (sparks from steel collisions can ignite).

*Disassembly under pressure: Accidentally opening a valve.

*High-pressure water jet injuries (lesson from a farmer who lost a finger).

English

English русский

русский 日本語

日本語 عربى

عربى Español

Español