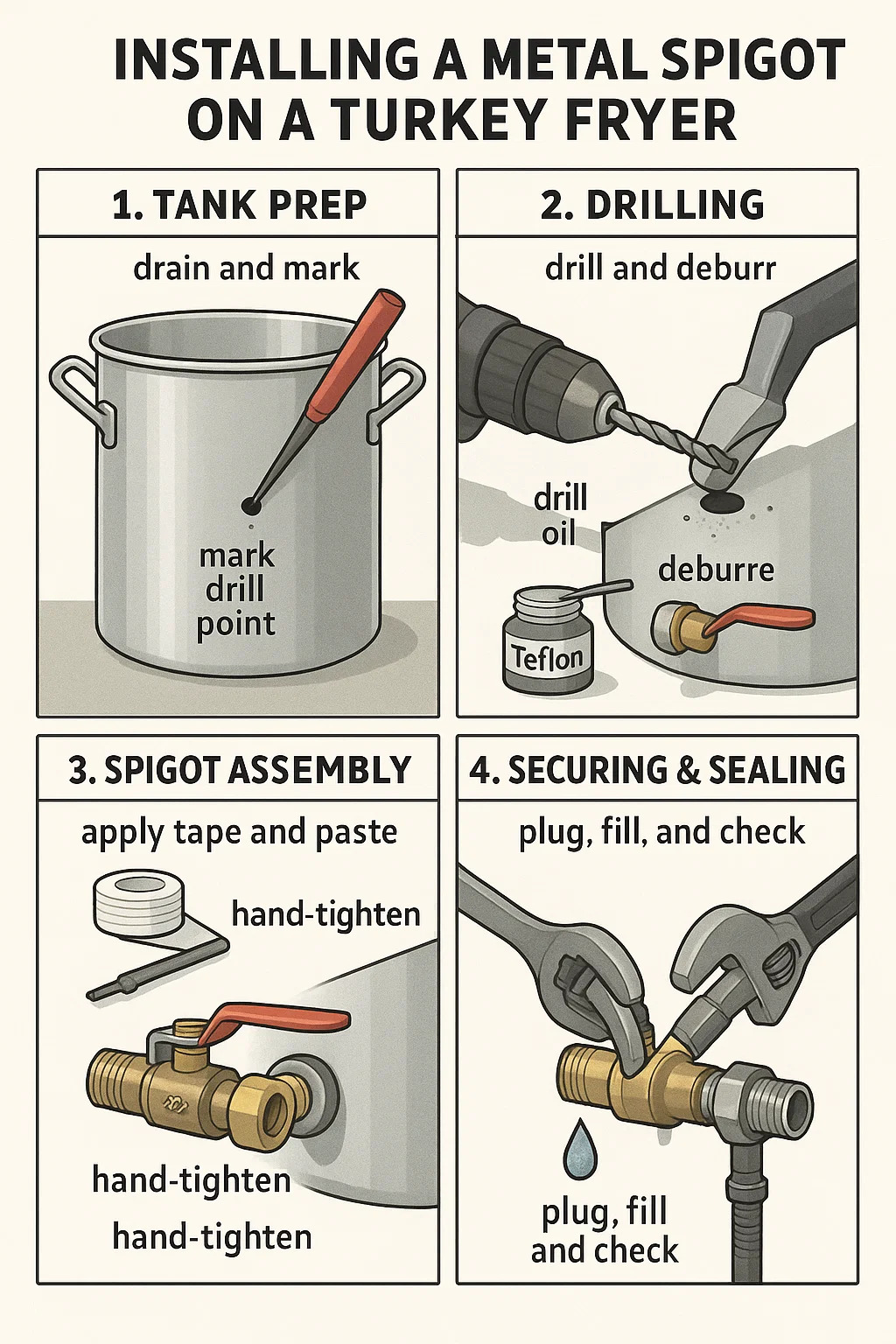

Here's a step-by-step guide for installing a metal spigot on a turkey fryer:

Core Tools & Materials

Metal spigot: Bronze or stainless steel (zinc alloys melt at frying temps)

Step drill bit (for clean hole in thin metal)

Teflon tape + high-temp pipe dope

Adjustable wrench + channel locks

Center punch + safety goggles

Installation Process

1. Tank Prep

Drain residual oil completely – wipe interior with rags until dry

Mark drill point:

Ideal position: 1" above fryer’s lowest curve (avoids sediment clogs)

Avoid weld seams (weak points) – tap tank to find “drum” sound areas

2. Drilling

Punch starter dimple to prevent bit walking

Lubricate drill bit with cutting oil (reduces burrs)

Slow-speed drilling: Start with ¼" bit → step up to spigot size (e.g., ⅜" NPT)

Deburr hole: Use round file on both sides – removes sharp edges that crack seals

3. Spigot Assembly

Wrap male threads:

3 clockwise turns of Teflon tape (facing thread direction)

Coat with nickel-based anti-seize paste (seals >500°F)

Hand-tighten spigot into tank until seated – DO NOT CRANK

4. Securing & Sealing

Backup wrench inside: Hold spigot base with channel locks inside tank

External tightening: Use adjustable wrench – ¼ turn past hand-tight (soft metal threads strip easily)

Seal test: Plug spigot → fill tank with water → check for weeping at threads

Critical Warnings

Meltdown risk: Plastic valves will FAIL – use full-metal ball valves only

Thermal expansion gap: Leave ⅛" clearance between handle and tank (prevents binding when hot)

Oil drainage safety:

Install downward-angled extension pipe (directs oil away from feet)

Never drain >300°F oil – spigot heat softens seals

English

English русский

русский 日本語

日本語 عربى

عربى Español

Español