Content

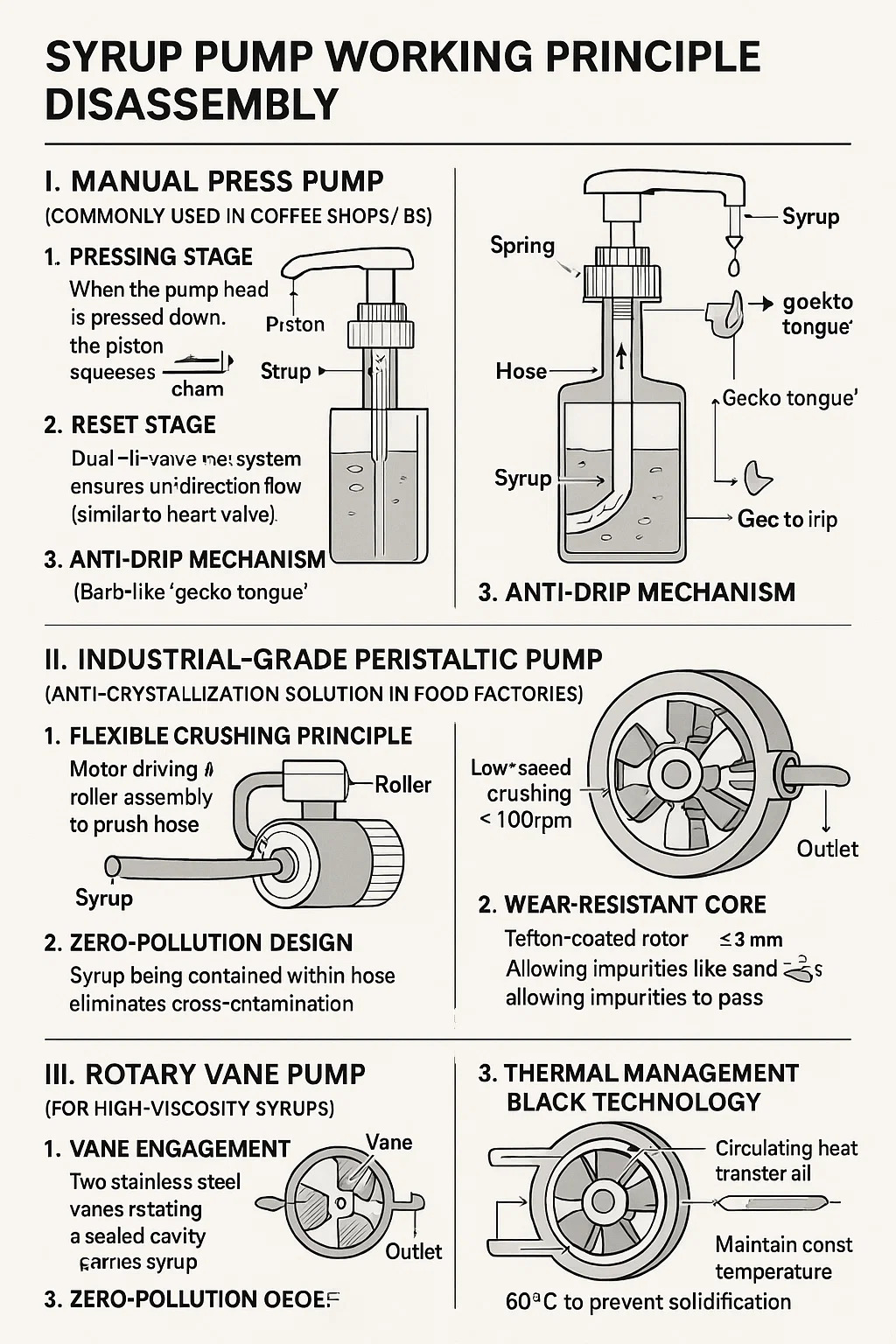

Syrup Pump Working Principle Disassembly

I. Manual Press Pump (Commonly Used in Coffee Shops/Bars)

1. Pressing Stage: When the pump head is pressed down, the piston squeezes the chamber → the bottom one-way valve closes → syrup is forced out from the outlet pipe.

Starbucks' "2P" sign means two presses (each pump ≈ 6 ounces of syrup).

2. Reset Stage: When the pump head is released, the spring lifts the piston → the top ball valve locks to prevent backflow → the bottom valve opens, creating negative pressure to draw in new syrup.

Key Design: The dual ball valve system ensures unidirectional flow (similar to heart valves).

3. Anti-Drip Mechanism: The barbed "gecko tongue" structure at the outlet → ensures zero residue when syrup flow is interrupted.

II. Industrial-Grade Peristaltic Pump (Anti-Crystallization Solution in Food Factories)

1. Flexible Crushing Principle: The motor drives the roller assembly to crush the hose → the crushing point moves forward, creating negative pressure to draw in syrup.

The hose springs back to its original shape → continuously drawing in new syrup.

2. Zero-Pollution Design: Syrup only contacts the food-grade hose (avoiding metal parts) → Eliminating cross-contamination.

The hose is resistant to fruit acid corrosion (e.g., reinforced with 316L stainless steel).

3. Crystallization Breaking Technique: Low-speed crushing (<100rpm) → Avoids frictional heating → Prevents syrup crystallization and hardening.

III. Rotary Vane Pump (For High-Viscosity Syrups)

1. Vane Engagement: Two stainless steel vanes rotate in opposite directions → The tooth gap forms a sealed cavity carrying the syrup.

The cavity moves to the outlet → The vanes engage, squeezing and expelling the syrup.

2. Wear-Resistant Core: Vane-to-Pump Housing Gap ≥3mm → Allows sand particles to pass through without jamming (cane syrup contains impurities).

Teflon-Coated Rotor → Reduces friction and sugar crystal formation.

3. Thermal Management Black Technology: Circulating heat transfer oil in the pump body jacket → Maintains a constant temperature of 60℃ to prevent solidification.

English

English русский

русский 日本語

日本語 عربى

عربى Español

Español