Content

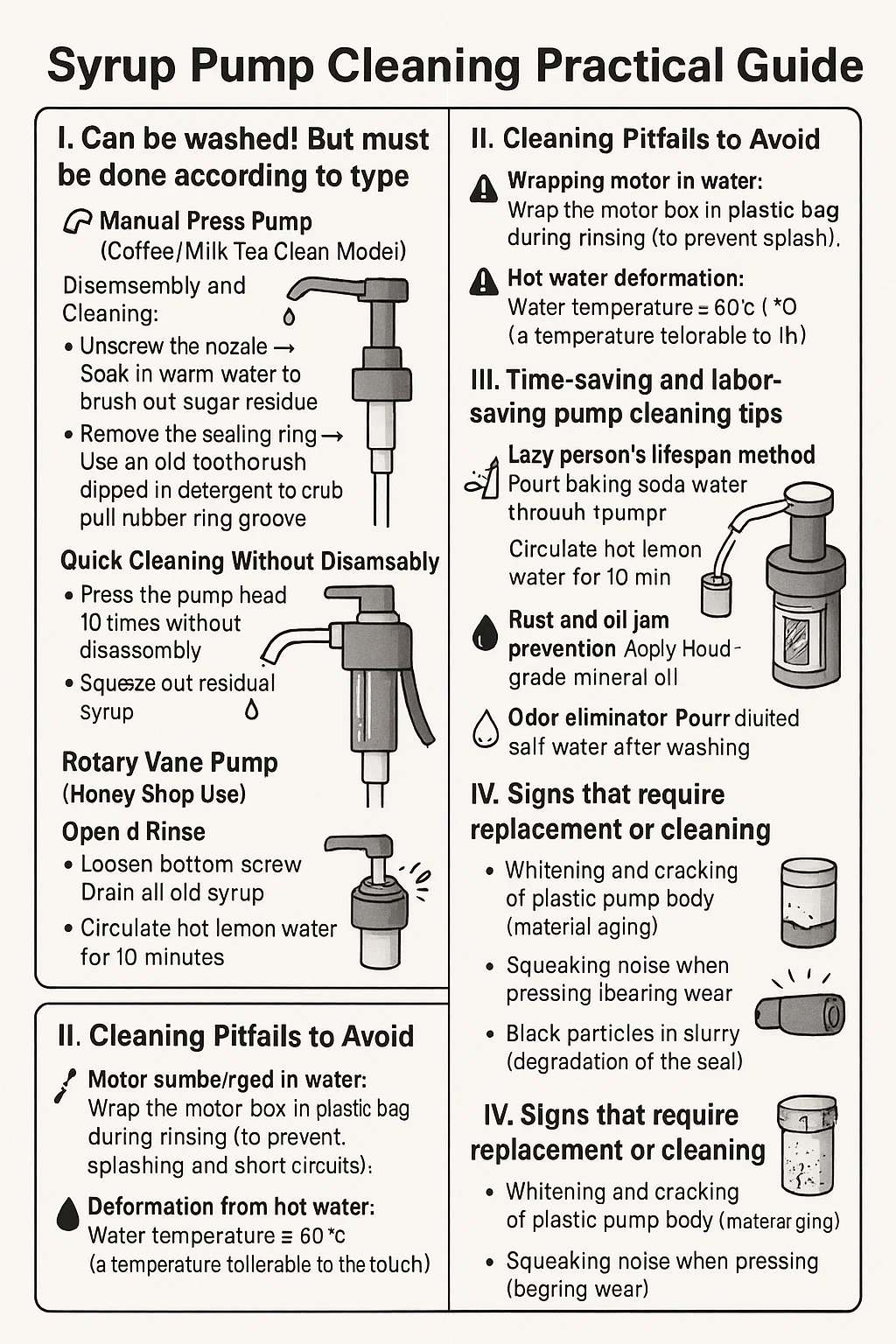

Syrup Pump Cleaning Practical Guide

I. Can be washed! But must be done according to type

● Manual Press Pump (Coffee/Milk Tea Shop Model)

Disassembly and Cleaning:

• Unscrew the nozzle → Soak in warm water to brush out sugar residue

• Remove the sealing ring → Use an old toothbrush dipped in detergent to scrub the rubber ring groove

Quick Cleaning Without Disassembly:

• Press the pump head 10 times without disassembly → Squeeze out residual syrup

• Wrap a wet cloth around the outlet → Press the pump upside down → Suction away residual liquid

● Industrial Peristaltic Pump (Large Machines in Jam Factories)

Focus on Cleaning the Hose:

• Disassemble the hose → Turn it over and rinse with water (like washing rain boots)

• Insert a straw into the hose opening → Blow air to check for airflow

Roller Maintenance:

• Wipe the roller groove with a cotton swab dipped in alcohol (to prevent sugar crystallization from causing jamming)

● Rotary Vane Pump (Honey Shop Use)

Open and Rinse:

• Loosen the bottom screw → Drain all old syrup

• Circulate hot lemon water for 10 minutes (to dissolve crystals)

II. Cleaning Pitfalls to Avoid

• Motor submerged in water: Wrap the motor box in a plastic bag during rinsing (to prevent splashing and short circuits).

• Deformation from hot water: Water temperature ≤ 60℃ (a temperature tolerable to the touch).

• Strong acid corrosion: White vinegar concentration ≤ 10% (1 cup vinegar + 9 cups water).

• Mold growth due to lack of drying: Use a compressed air gun to blow away water droplets from crevices.

III. Time-saving and labor-saving pump cleaning tips

● Lazy person's lifespan method:

Before changing sugar, pour baking soda water through the pump → the bubbles wash away the sugar film. Use a tea filter bag over the nozzle → to intercept impurities and reduce cleaning.

● Rust and oil jam prevention:

Apply food-grade mineral oil (or a glycerin suppository from a pharmacy) before reinstalling.

● Odor eliminator:

After washing, pour diluted salt water → to sterilize and remove odors.

● Master craftsman's secret tips:

For stubborn sugar stains, use a hairdryer to heat → soften and rinse off easily. For sticky sealing rings → sprinkle cornstarch to prevent sticking. Store spare pumps in pure olive oil.

IV. Signs that require replacement or cleaning

• Whitening and cracking of the plastic pump body (material aging).

• Squeaking noise when pressing (bearing wear)

• Black particles in the slurry (degradation of the seal)

English

English русский

русский 日本語

日本語 عربى

عربى Español

Español